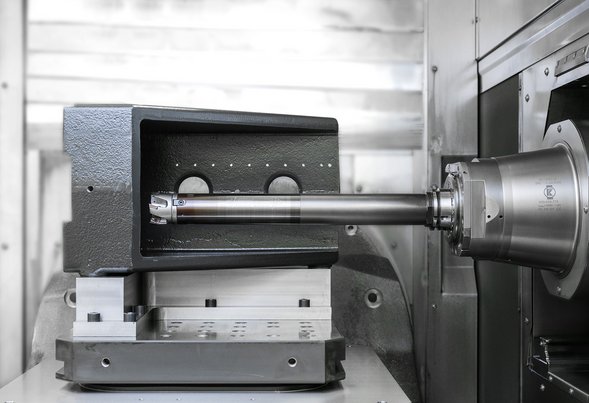

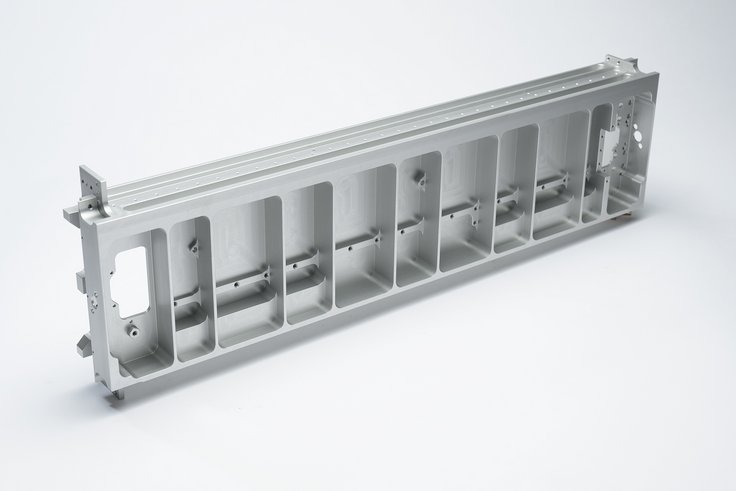

Milling

CNC 5-axis milling with 1400 tool places and over 200 pallet places

Our 5-axis machining centers can handle even the most complicated geometries. From single parts or prototypes to large and recurring quantities, we manufacture your products - with flexibilty across a wide range of variants.

The high-performance machines enable efficient production of complex components in just a few clamping operations. Our high quality standards rest on the combination of gentle clamping systems, automation and qualified personnel.

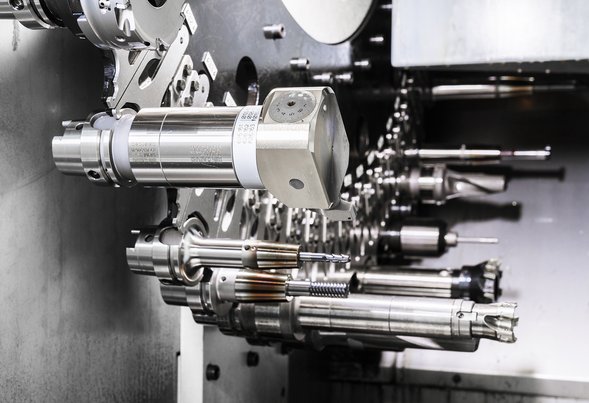

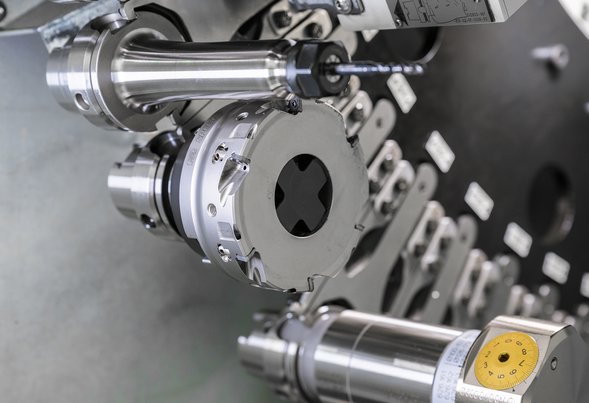

Grob G520 twin-spindle machines set new standards

We have been using two new systems since the end of 2024 and they offer the following added value:

- Economical production of series components

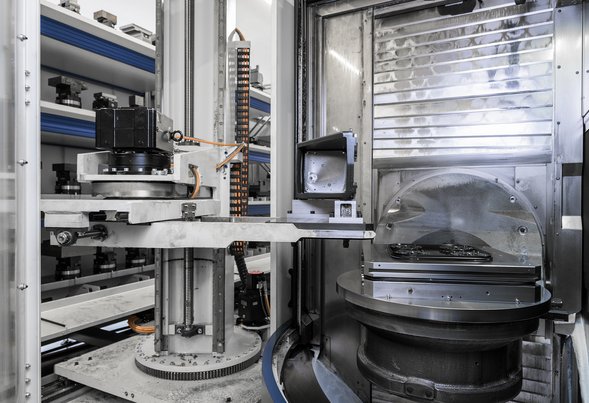

- Automated loading of the machines with robot

- Main time parallel flexible deburring and marking of the components

- In combination with high-pressure washing, an optimal solution for ready-to-install series components

- Independent Z-axes and automatically adjustable spindle distance in X-direction

- Complete pallet change in less than 10 seconds

- Setup and loading in parallel for maximum efficiency

The machines are programmed directly from your 3D data using a CAM system. We check machining programs for collisions and thus optimize set-up and run-in times.

We machine the following materials:

- aluminum alloys

- structural, construction and tool steel

- stainless materials

- gray and nodular cast iron