News

17.07.2024

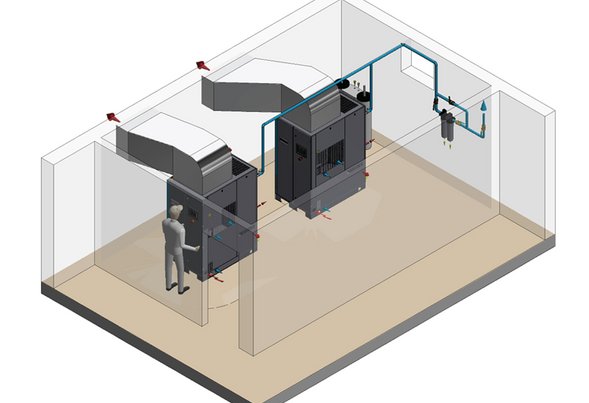

New compressor room

We have installed a new compressor room in order to improve our energy efficiency. This step has two key advantages! First, we will reduce our gas consumption by 70%, as we can use the waste heat effectively. Second, the more energy-efficient air compressors consume 15% less electricity for the same amount of compressed air. Incidentally, the old compressors will not be scrapped, but will be incorporated into Atlas Copco's rental fleet.

28.06.2024

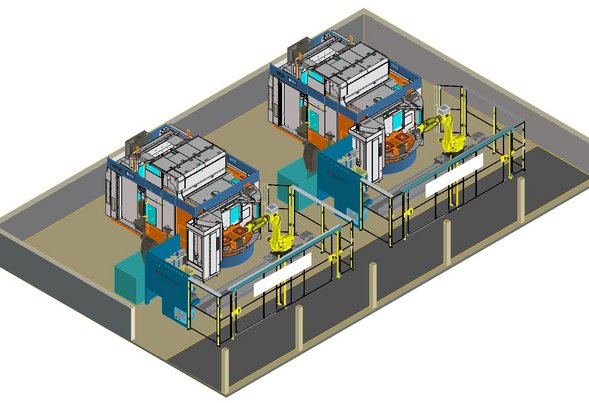

News from the construction site

We will bring two Grob G520 double-spindle machines into operation in autumn this year. This investment will enable us to significantly increase our performance and better meet customer requirements. We are currently converting our production hall for the two 35-ton machines. The floor has already been reinforced, the lighting installed and the high-speed door fitted. Next, the power supply, compressed air and fresh water supply, and recooling system will be installed. The machines are scheduled to arrive in the last week of August. We look forward to the commissioning and further construction progress.

25.09.2023

Grob G520 twin-spindle machines set new standards

We are investing again! We are setting new standards in terms of cost-effectiveness for the production of series components with two identical Grob G520 twin-spindle machines. We further maximize low-manpower production to, in combination with high-pressure washing, offer an optimal and complete solution for ready-to-install components by equipping the machines automatically with robots. Technical features such as independent Z-axes and automatically adjustable spindle distance in the X-direction add to the many advantages of the Grob machines. The systems will be in operation at our plant from the end of 2024.

11.07.2023

Sustainable electricity from our own production

We will produce a quarter of our electricity needs from our own solar energy from spring 2024! We are installing, in collaboration with Helion Energy AG, a 1,100 square meter photovoltaic system on the flat roof of our company building this fall. We are delighted to be able to make a contribution to the independent and sustainable supply of electricity in Switzerland.

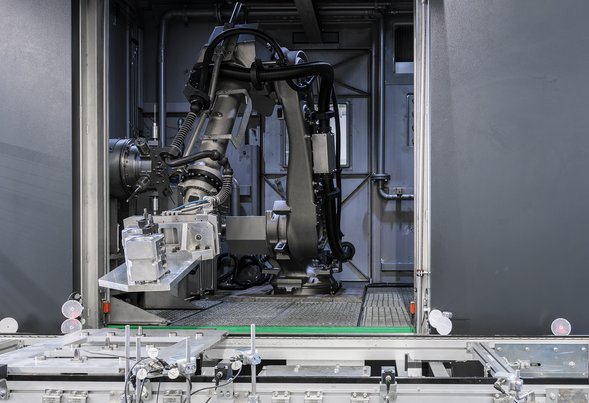

11.07.2022 NEW: Washing and deburring with high-pressure water jets up to 850 bar pressure

A 6-axis articulated robot arm and 13 different, independent cleaning tools achieve the best results for you when cleaning and deburring your components.

01.01.2022

Two in one - the Swiss manufacturing network

With "two in one”, several specialists who have different fields of expertise focus on the most important thing: you. For example, "two in one” combines know-how in casting production and metal cutting with other technologies to meet your specific requirements.

Mandatec has been part of this network since 2022 to offer our customers even more comprehensive services across different areas of expertise.

All network partners are technically and logistically interconnected. This means that you, as a customer, benefit from complete, bespoke solutions from a single source.

May 05, 2022: Operational! Our new - and Switzerland's first - washing and deburring robot is ready for use!

Our high pressure water jet washing and deburring system is operational and starting serial production.